Intelligent Metallurgy

Building a Green & Smart Future!

Efficiency

Anti-Interference

Integration

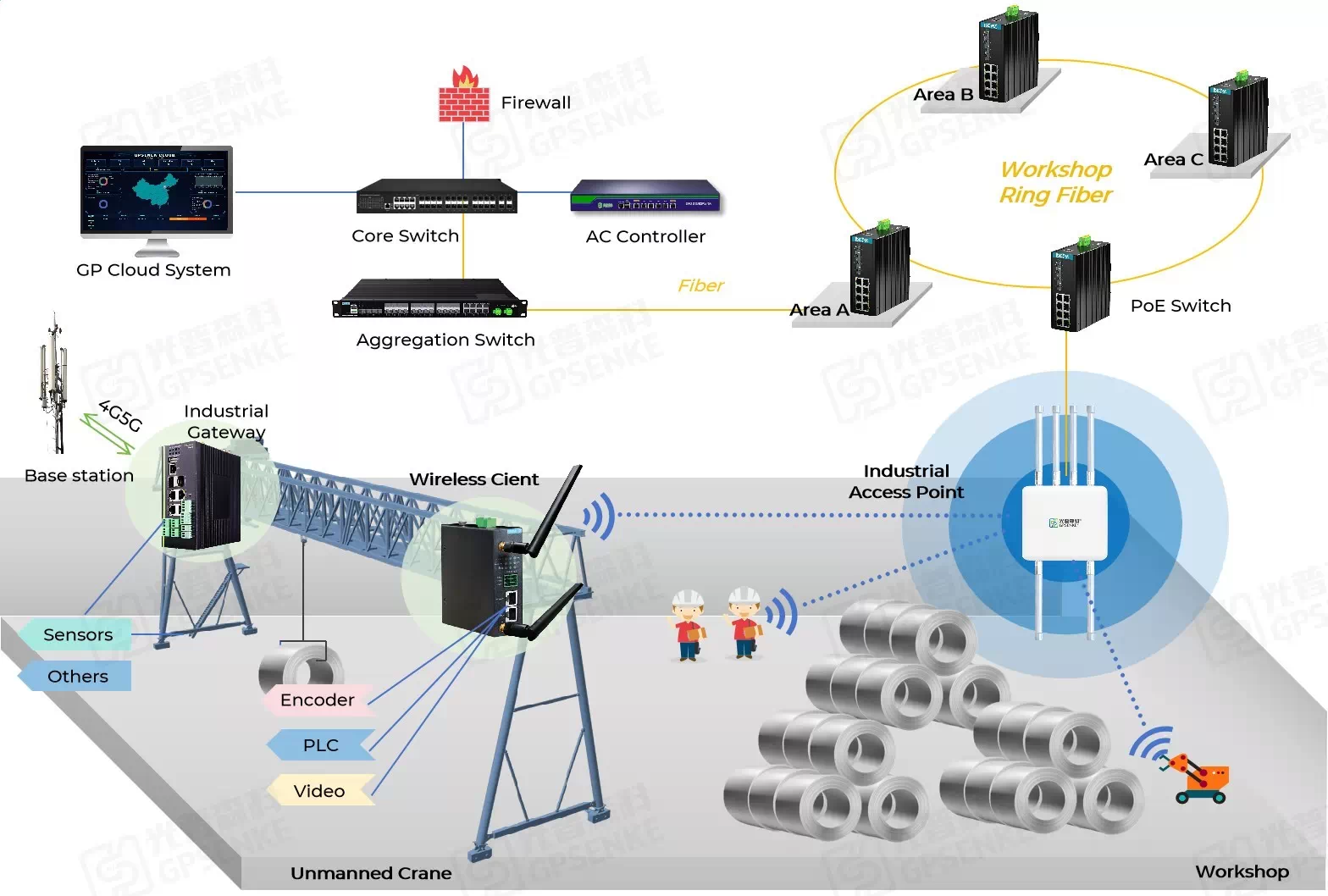

Wireless Communication Network for Cranes & Ground in Metallurgical Plant

In a large steel plant’s hot rolling workshop, cranes, as key material handling equipment, operate frequently and carry heavy tasks. To improve production safety and operational flexibility, the client proposed remote control of the crane from the ground, along with real-time access to high-definition video footage and PLC control data from the crane.

Ensuring Stable Communication for Video Surveillance and Real-Time PLC Control!

Core Objective

Technical Challenges

- Precise Ground Control of Crane Movement

- Real-time Transmission of Camera Feed and PLC Operational Status

- Establish a Highly Reliable, Low-Latency, High-Bandwidth Industrial Wireless Communication System.

- High Temperature & Interference: Metal components cause signal disruption.

- Real-Time Control: PLC delays impact crane safety.

- Dual Stream Transmission: Control signals and HD video transmission challenge bandwidth.

- Unstable Mobile Link: Seamless switching during crane movement.

- PN Protocol & Prioritization: Ensure PLC signal priority.

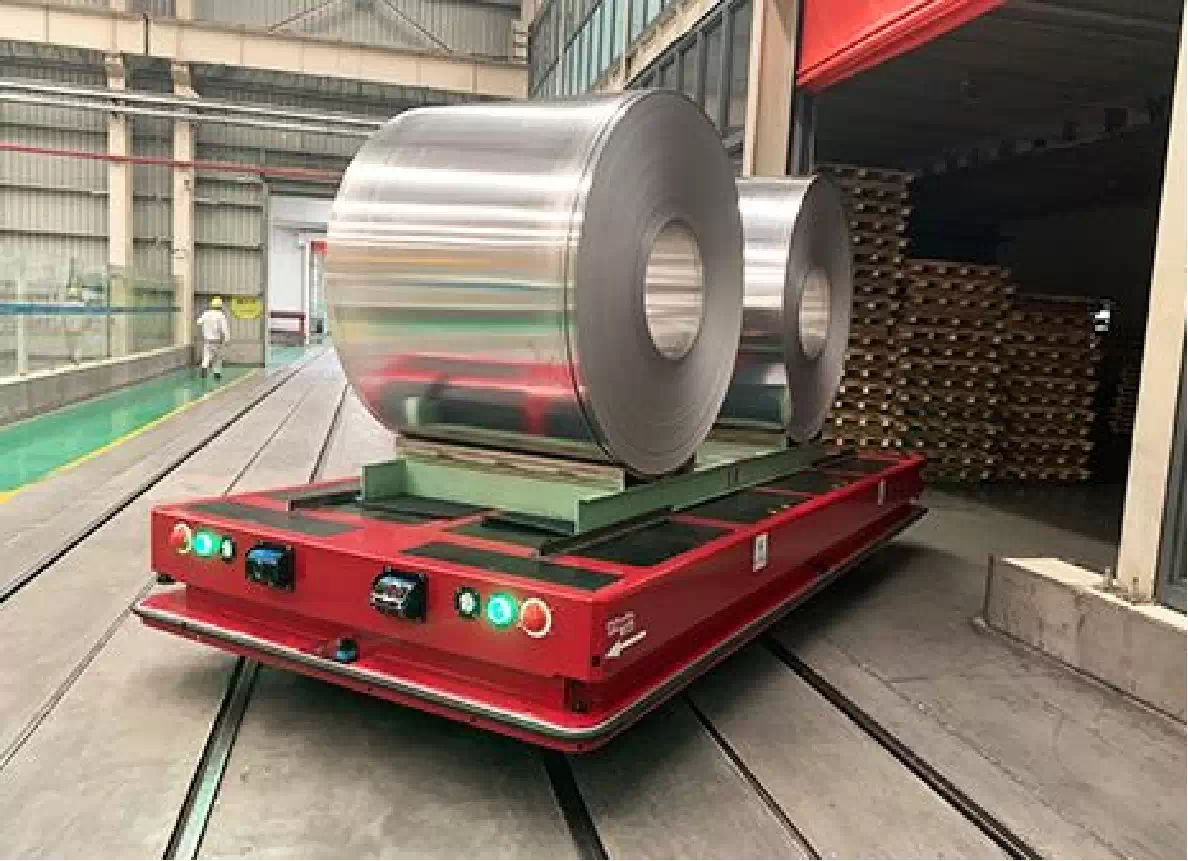

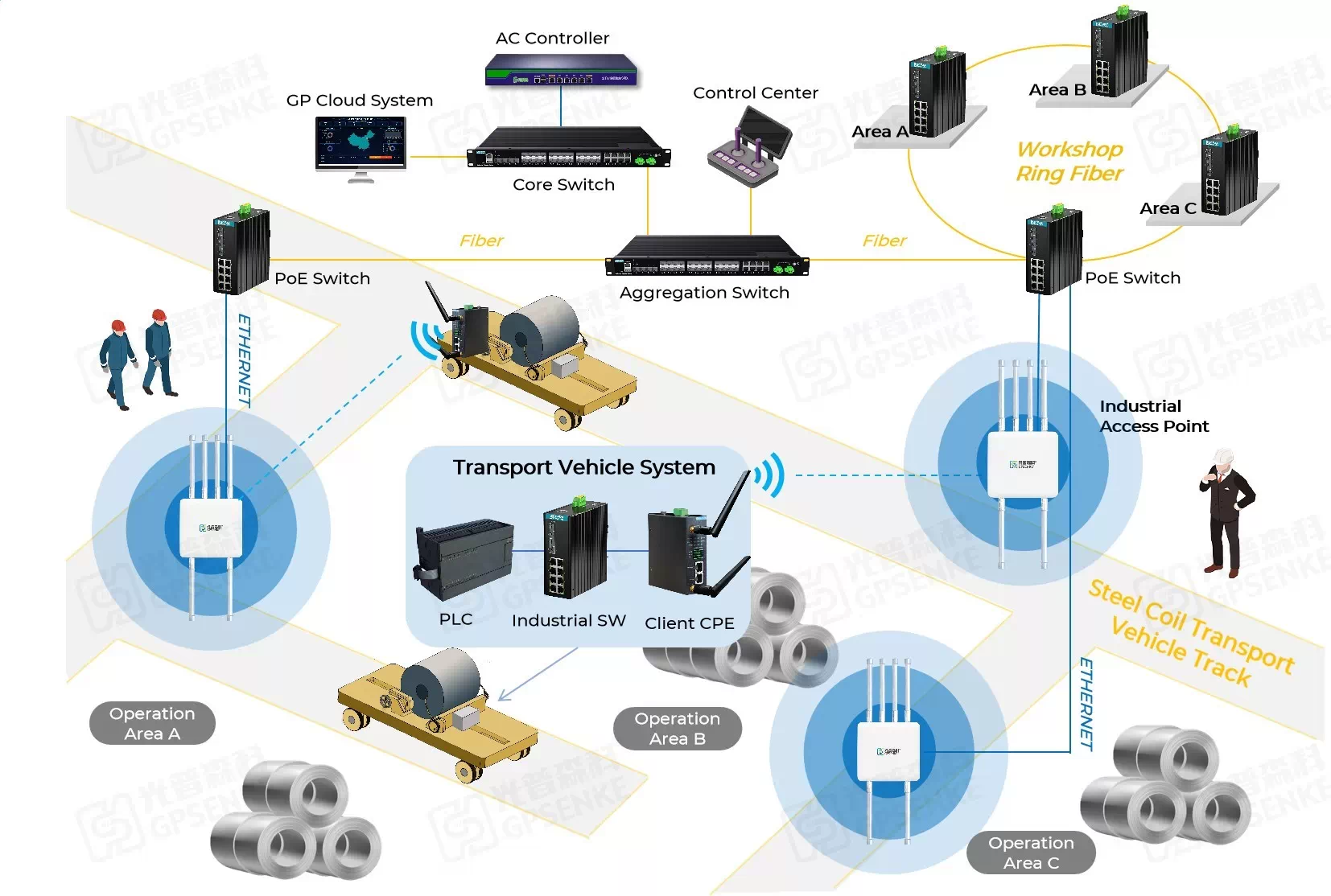

Hot Rolling Transport Vehicles & Remote Control System

In the hot rolling workshop, track-bound transport vehicles move steel coils. Traditional wired systems are limited by fixed wiring and require costly rewiring with layout changes. This project uses a wireless communication system to connect vehicles and the remote console, enabling real-time monitoring and precise control, improving efficiency and flexibility.

Ensuring Wireless Remote Control and Real-Time Monitoring of Transport Vehicles!

Core Objective

Technical Challenges

- Wireless Control: Remote control of transport vehicles.

- Signal Stability: Reliable communication in harsh environments.

- Real-Time Monitoring: Vehicle location and status tracking.

- Flexible Deployment: Easy layout adjustments, no rewiring needed.

- High Real-Time Requirements: The PLC on the transport vehicle is sensitive to communication delays, requiring millisecond-level response.

- Complex Industrial Environment: Metal obstructions in the hot rolling workshop cause multipath interference and signal attenuation.

- Wide Coverage Challenge: Transport vehicles move across multiple areas, requiring continuous, stable wireless network coverage without interruptions.

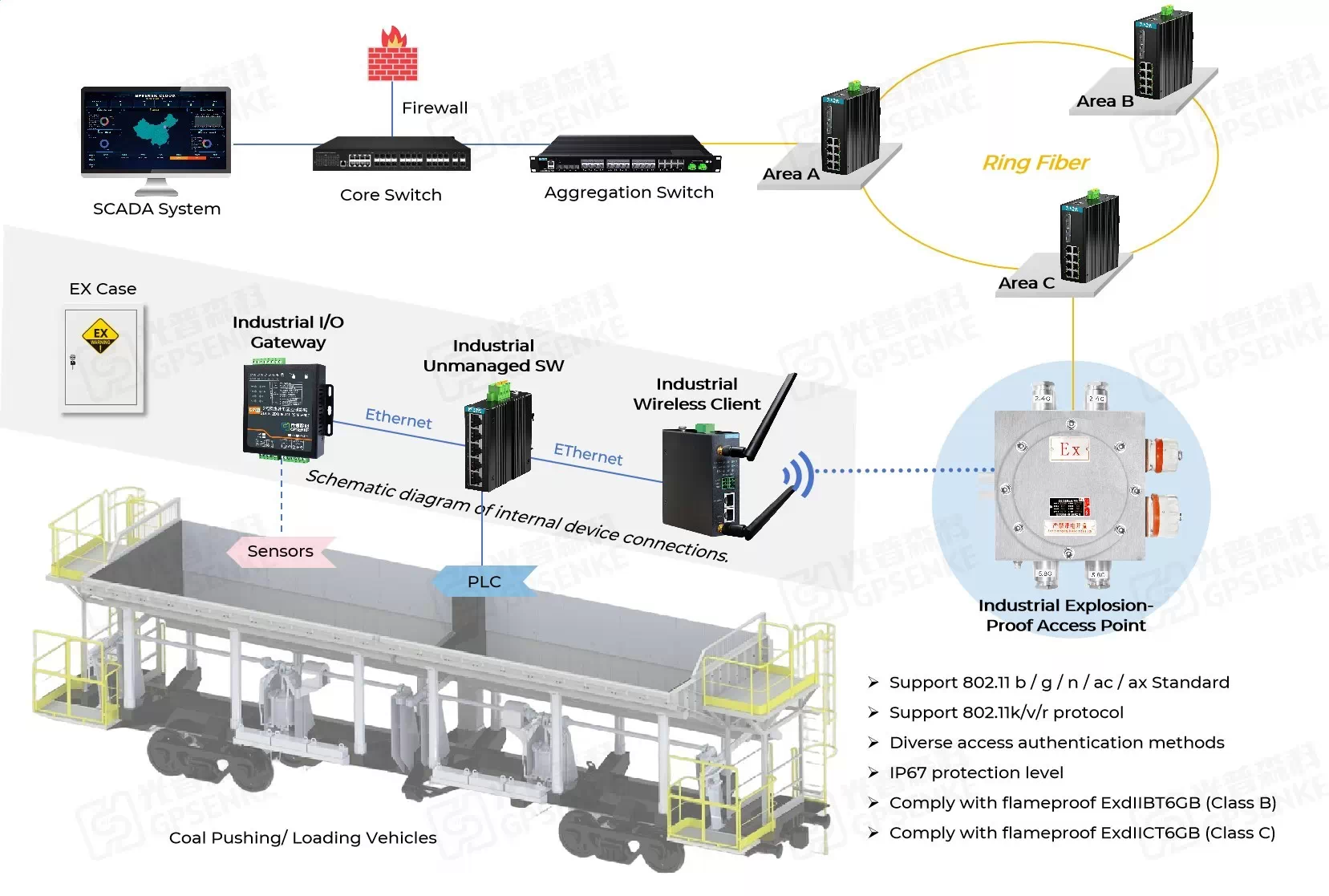

Coke Plant Network for Pushing & Loading Operation Vehicles

With the increasing automation and environmental demands in coke plants, vehicles like pusher cars and coal loading cars generate large amounts of operational data. This project uses Wi-Fi technology to efficiently collect and transmit this data to the central system, enabling better decision-making and timely fault warnings.

Ensuring Efficient Data Transmission and Collection for Smart Operation Vehicles

Core Objective

Technical Challenges

- Real-time wireless data upload from vehicles to enhance efficiency.

- Remote monitoring of vehicle status to improve safety.

- Ensure reliable wireless operation in harsh environments.

- Unified device integration for intelligent vehicle management.

- Explosion-proof: Devices must meet safety standards in hazardous areas.

- Temperature Range: Equipment must work from -40°C to 75°C.

- Electromagnetic Interference: Devices must resist interference from inverters.

- Protocol Support: System needs to handle multiple industrial protocols.

- Roaming: Fast, stable wireless switching during vehicle movement.

Unmanned Inspection Networks in Aluminum Plant

The production process of an aluminum electrolysis plant is complex, with harsh operating environments and high safety requirements. The unmanned inspection system utilizes wireless communication, video surveillance, and sensor technologies to achieve comprehensive intelligent monitoring of the production site. The system can collect real-time operational data from key equipment such as electrolytic cells, aluminum electrolysis devices, and power supply systems, monitoring parameters like temperature, pressure, and current, and performing automated data analysis. The data is transmitted to the central monitoring platform via wireless networks, allowing remote operators to view equipment status in real-time, detect faults promptly, and issue alarms.

Ensuring Efficient Data Transmission and Collection for Smart Operation Vehicles

Core Objective

Technical Challenges

- Real-time wireless data upload from vehicles to enhance efficiency.

- Remote monitoring of vehicle status to improve safety.

- Ensure reliable wireless operation in harsh environments.

- Unified device integration for intelligent vehicle management.

- Explosion-proof: Devices must meet safety standards in hazardous areas.

- Temperature Range: Equipment must work from -40°C to 75°C.

- Electromagnetic Interference: Devices must resist interference from inverters.

- Protocol Support: System needs to handle multiple industrial protocols.

- Roaming: Fast, stable wireless switching during vehicle movement.