Oil & Gas Industry

Building a Green & Smart Future!

E.X Standard

High Reliability

Integration

Digital Oilfield Wellhead

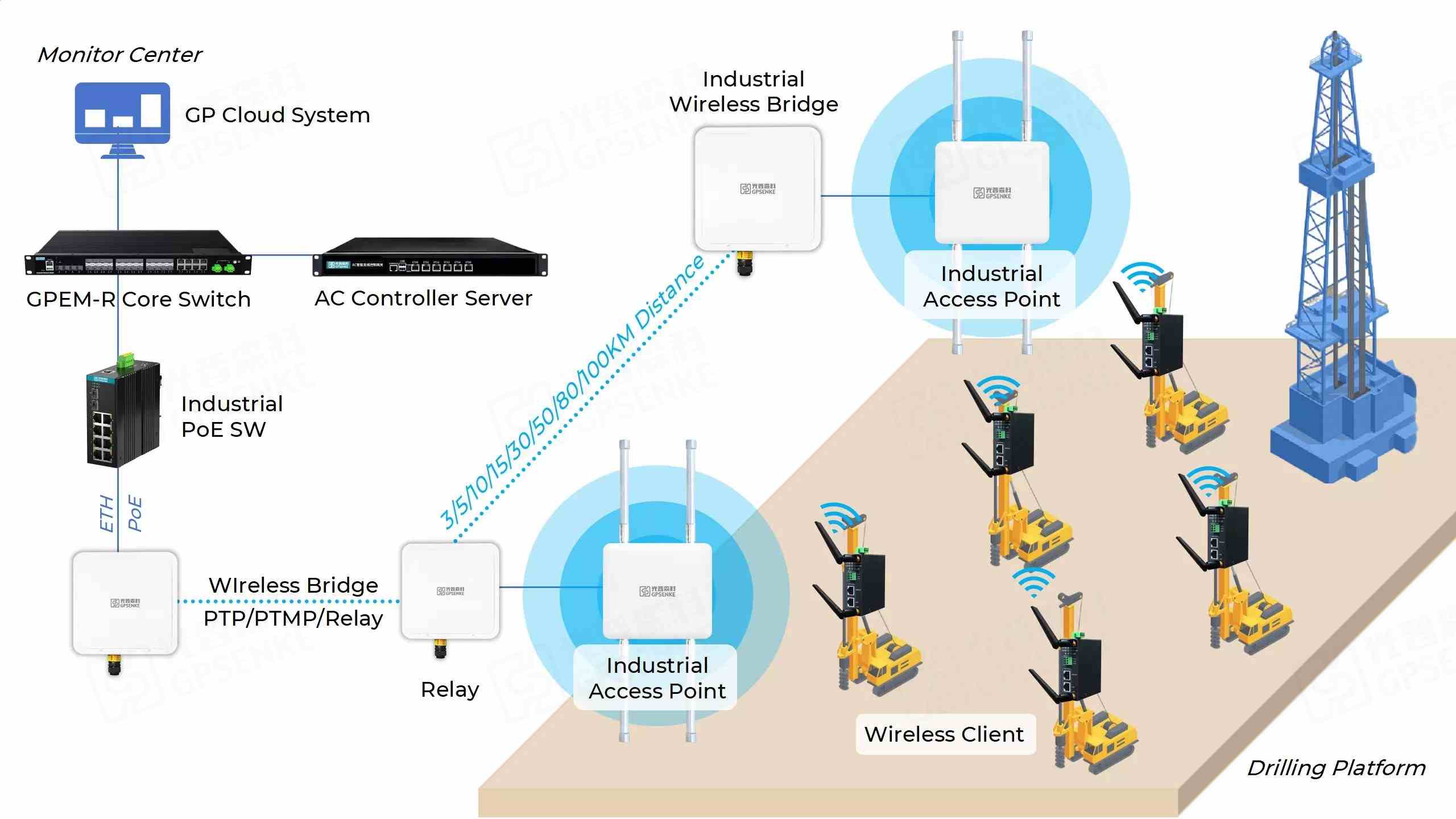

During oil or gas drilling, cement slurry is injected into the wellbore to prevent the mixing of oil, gas, and water layers. Cementing operations often require multiple cement trucks working together, with real-time data recording and analysis. To address the mobility of cement trucks, GPSENKE has introduced a wireless communication solution. By installing wireless APs on command vehicles, a local area network (LAN) is formed, enabling internal communication. For long-distance data transmission to the central location, wireless bridges are used, ensuring seamless connectivity across the site.

Cementing operations for wellbore integrity sometimes require multiple cement trucks to work together, enabling real-time recording, analysis, and storage of operational data. Due to the random deployment and non-fixed positions of multiple cement trucks, originally connected by wired systems, we have introduced a wireless communication networking solution to address issues related to vehicle mobility and timely data collection and transmission. This involves installing wireless access points (APs) on command vehicles to establish wireless connections with other cement trucks, forming a local area network (LAN) to facilitate internal communication. Additionally, if data transmission to a central location is required at the project site, wireless bridges can be selected for long-distance transmission to the center.

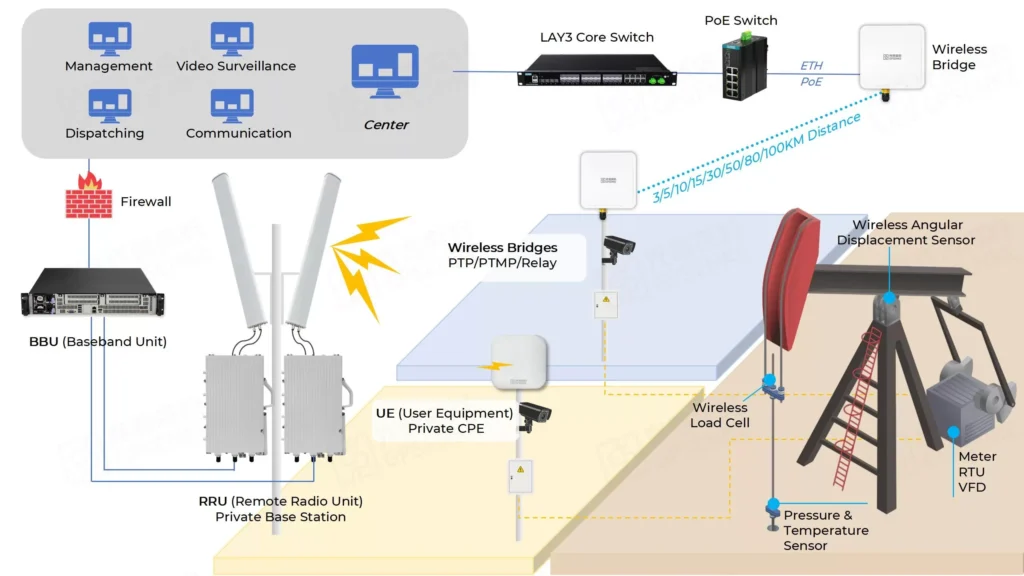

Digital Oil Extraction

On-site drilling data transmission and collection require real-time monitoring and uninterrupted redundant communications. (On-site drilling need to collection and alarm of abnormal data such as no oil from the oil well, excessive back pressure in winter, oil pipe blockage, oil theft, power outage, voltage instability, motor phase loss, low balance rate, etc.)

In oil extraction operations, the data transmission from the sucker rod pump (also known as the beam pump) is critical for ensuring real-time, stable data flow, supporting on-site operations and remote monitoring. The following are two data transmission methods we offer:

4G/5G Private Network Base Station Transmission:

Deploying a private 4G or 5G base station on-site enables efficient and reliable wireless communication for the sucker rod pump. The private network base station connects with terminal devices, such as the sucker rod pump, supporting real-time data transmission, remote monitoring, and control. This method offers high data transmission rates and maintains excellent communication quality in harsh environments, making it suitable for large-scale device interconnection & data collection.

Wireless Bridge Transmission:

Wireless bridges can be used for long-range data transmission between the sucker rod pump and the remote control center. By establishing point-to-point wireless connections, bridge devices provide stable wireless communication even in complex terrain and harsh environments, ensuring real-time data transmission with low latency. This method is ideal for large oil extraction sites, especially when fixed network lines are unavailable.

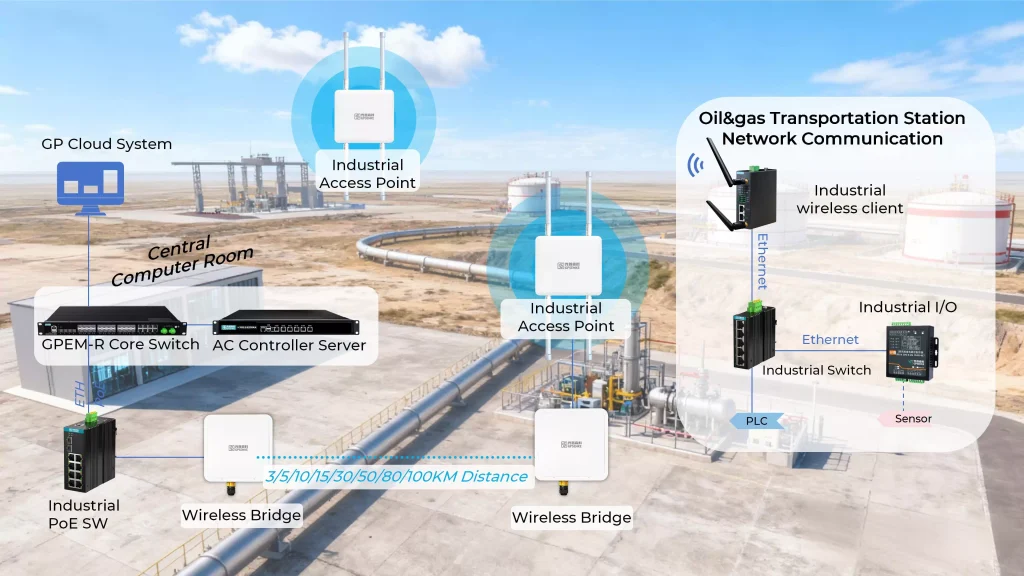

Oil&Gas Pipeline Real-Time Monitoring Network System

Oil and gas pipelines require real-time monitoring of critical data such as flow, pressure, and temperature to detect leaks or anomalies. GPSENKE provides stable and reliable wireless communication solutions that ensure seamless data transmission across vast areas and harsh environments. Our devices support remote monitoring and diagnostics, helping improve pipeline safety and efficiency while minimizing potential risks.

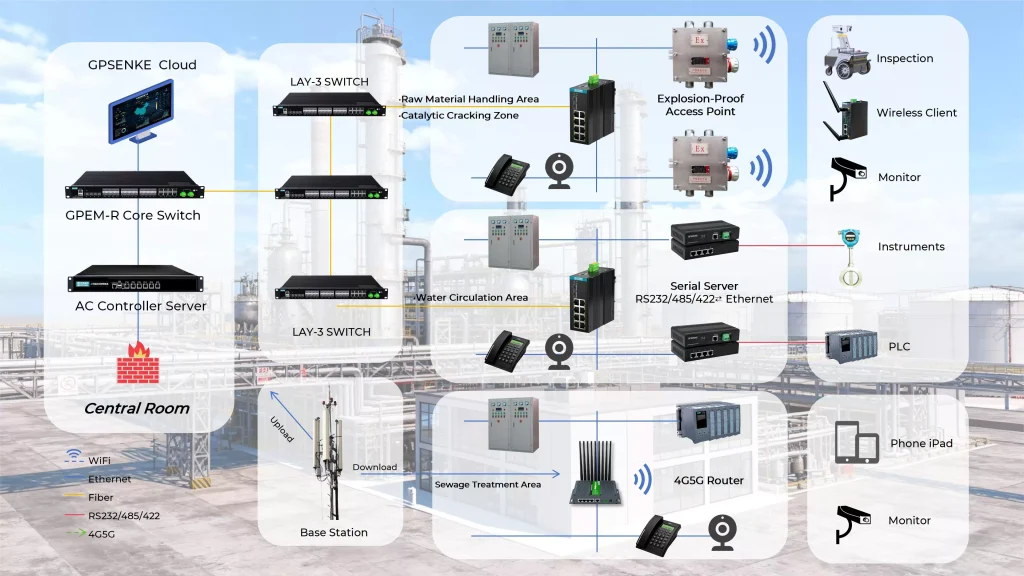

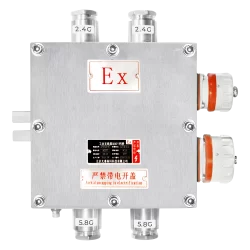

Petrochemical & Refinery Plant

Oil refineries operate in complex and hazardous environments, requiring communication systems with explosion-proof design and high safety standards. Real-time monitoring of key parameters such as temperature, pressure, and flow is crucial, especially in explosion-prone areas. GPSENKE offers wireless solutions that comply with explosion-proof standards, ensuring reliable operation in extreme conditions. Our devices seamlessly integrate with SCADA systems, enabling real-time monitoring and automated control, improving both the safety and efficiency of refinery operations.