Smart Mining

Building a Green & Smart Future!

Customizable

High Reliability

Integration

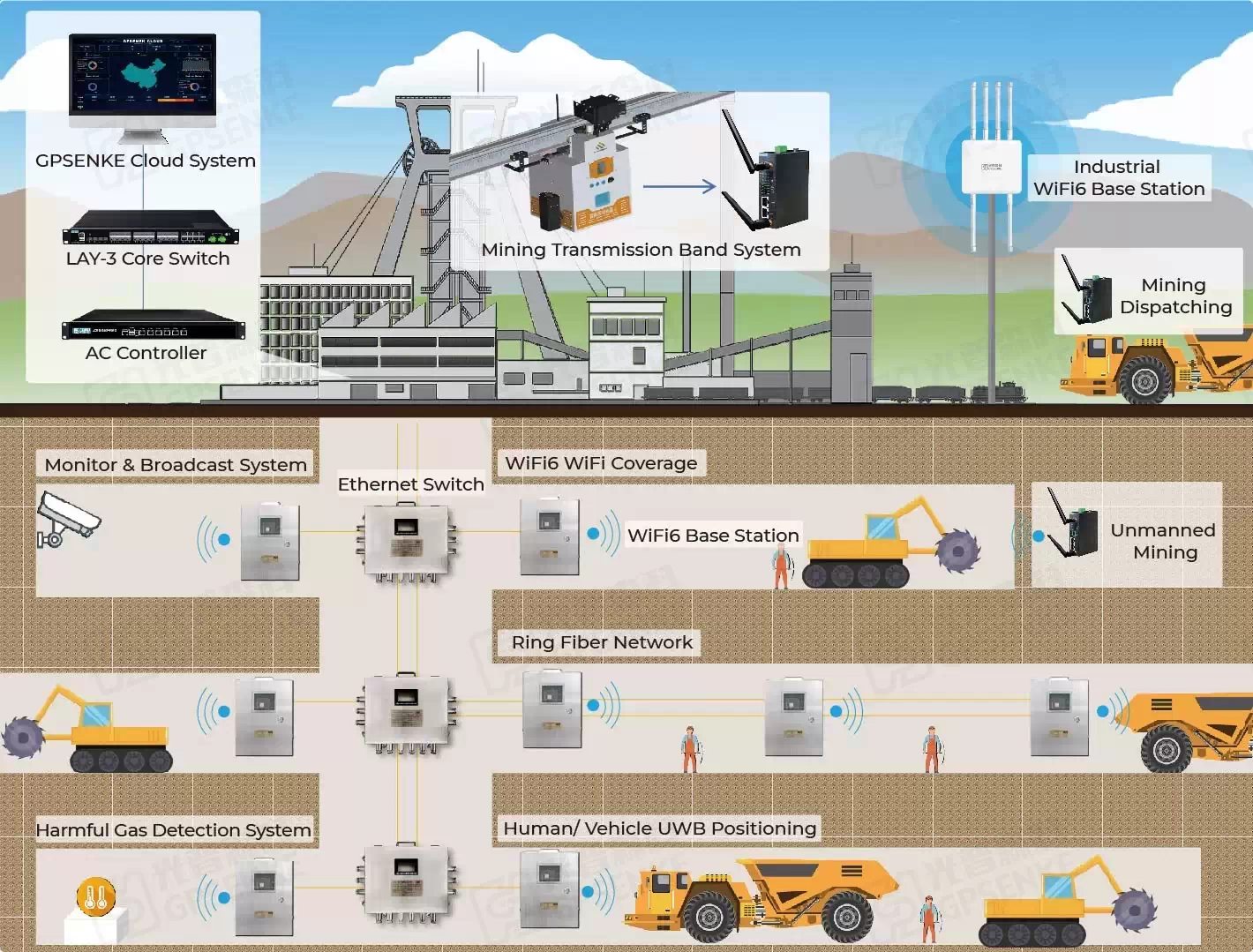

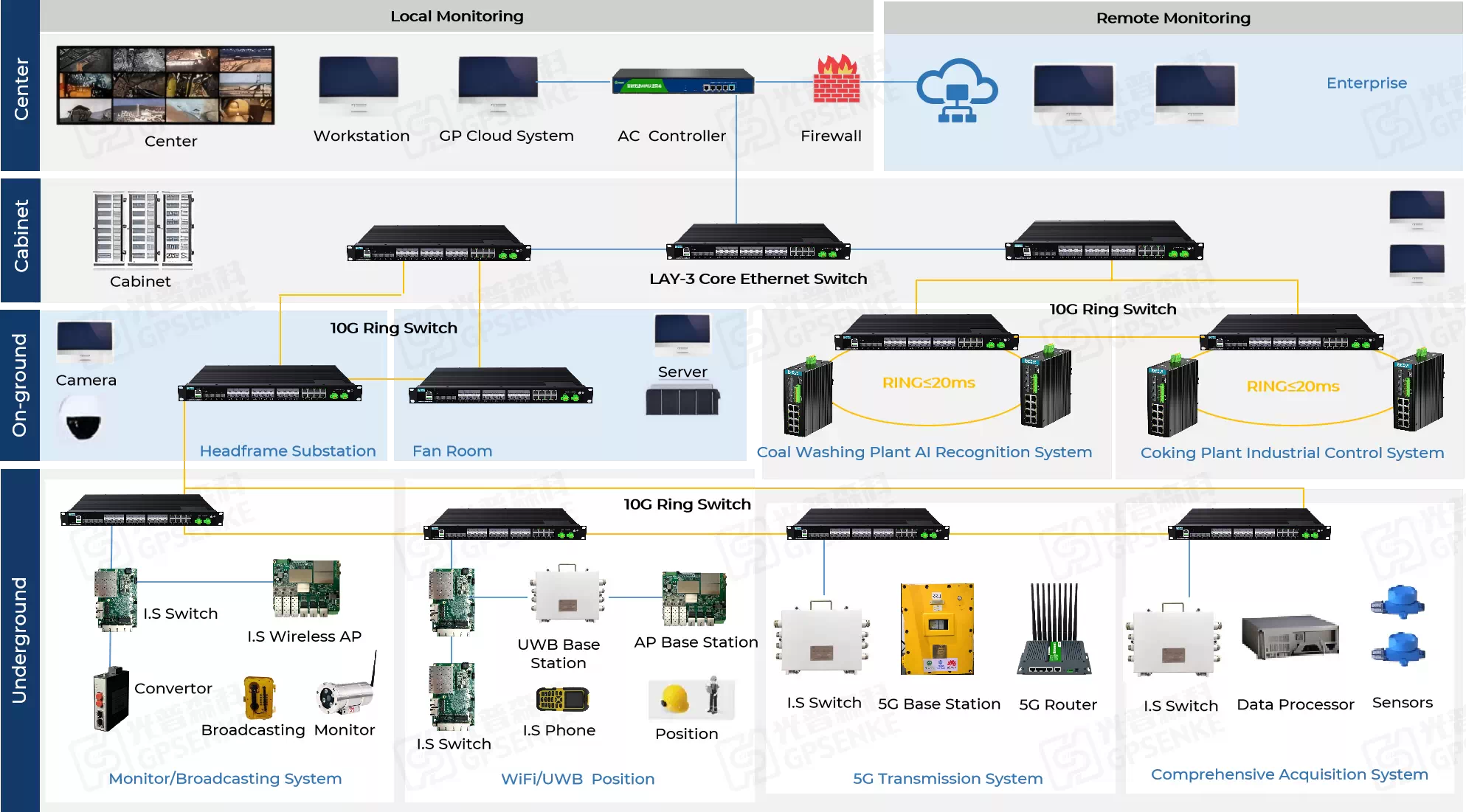

Underground Mining

The underground coal mining industry relies on key systems like integrated base stations, network communication, personnel positioning, video surveillance, broadcast communication, and environmental monitoring to ensure safety and efficiency. These systems provide real-time data on miner locations, equipment status, and environmental conditions, enabling quick responses to emergencies and optimizing operations. Through a unified platform, they enhance safety, operational efficiency, and emergency management.

Underground Integrated Base Station

Video Surveillance System

Personnel Positioning System

Environmental Monitoring System

- Broadcast Communication System

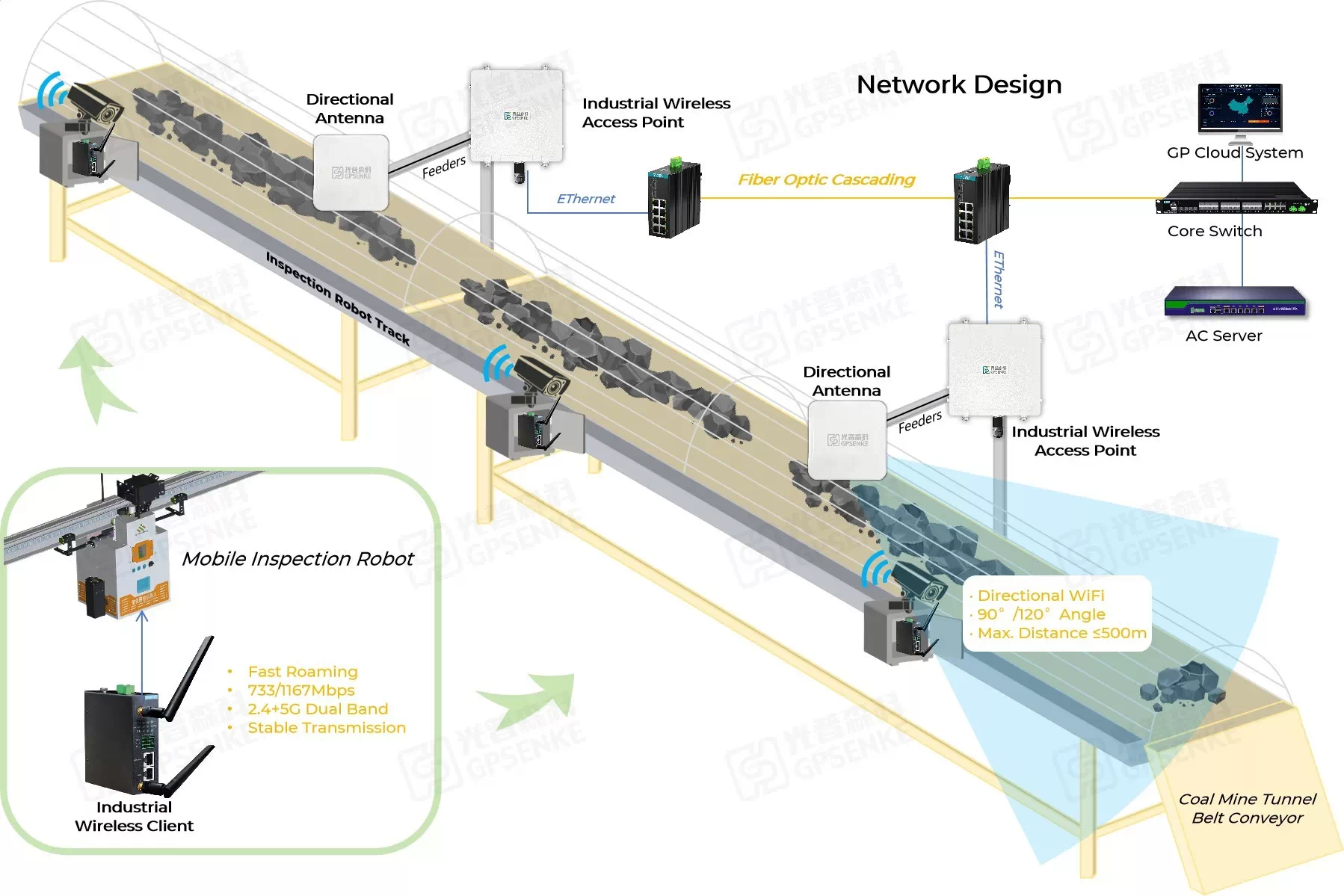

Coal Mine Tunnel Belt Conveyor Inspection

The coal washing plant conveyor belt video monitoring system uses wireless communication technology and high-definition cameras to transmit video data from the production line in real-time, ensuring smooth and safe coal transport. The system connects wirelessly to a central monitoring platform, enabling remote viewing and real-time analysis, which improves the operator’s response speed. The video data is not only used for monitoring but also integrates with other system devices (such as personnel tracking and environmental monitoring) to ensure the stable operation of equipment and safety during coal transport. Through integrated communication, the coal washing plant can effectively reduce manual inspections, enhance production efficiency, and ensure stable transport system operation.

Wireless Communication Support: The system transmits video data in real-time via wireless networks to the monitoring platform, enabling remote management and immediate feedback.

Wireless Communication Support: The system transmits video data in real-time via wireless networks to the monitoring platform, enabling remote management and immediate feedback.

Remote Control and Management: Operators can access real-time video remotely, reducing on-site inspections and improving management efficiency.

System Integration: The video monitoring system seamlessly integrates with other management systems (such as personnel tracking and environmental monitoring) for comprehensive data sharing and transport scheduling.

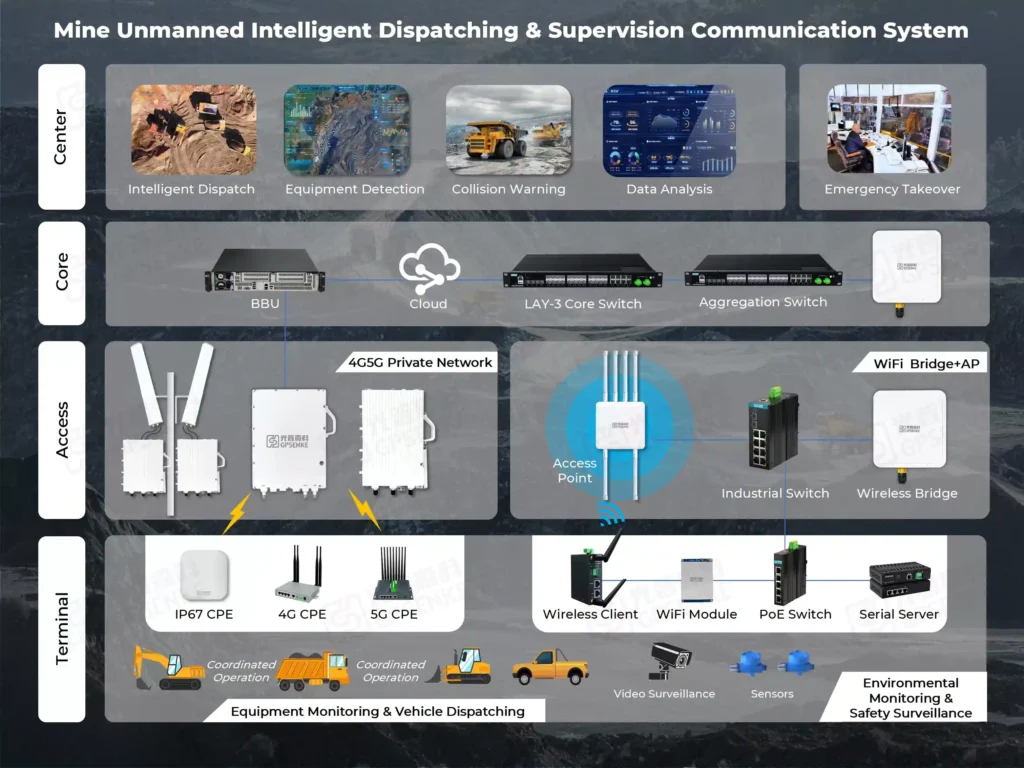

Mining Dispatching

Our mining dispatch solution builds a reliable communication network by deploying either a local area network (LAN) or 4G/5G private network base stations. These networks enable real-time connectivity between equipment, personnel, and transport vehicles within the mine, ensuring smooth information flow and precise scheduling. The base stations support high-speed data transmission and real-time monitoring, improving mining efficiency and reducing equipment downtime. Additionally, the solution supports remote monitoring and data analysis, allowing for early detection of potential risks and enabling proactive responses to ensure the safety and continuity of mining operations.