Automation Manufacturing

Building a Green & Smart Future!

Anti-Interference

High Reliability

Integration

Product Line

In smart manufacturing, production line monitoring systems use IoT and real-time data analytics to track production progress, equipment status, and quality control. They automatically detect bottlenecks and failures, issuing alerts to ensure smooth production. Integrated with ERP and MES systems, the monitoring system provides full production visibility, optimizing resource allocation, improving efficiency and product quality. In high-risk industries, the system monitors key parameters in real-time, ensuring stable equipment operation and responding promptly to anomalies, enhancing production safety.

Upgrading···

Automated Factory

In intelligent manufacturing, unmanned factories rely on fully automated and intelligent production systems, where all processes are autonomously executed by robots, sensors, and smart devices. Through IoT technology and real-time data analysis, the system monitors equipment status, production progress, and quality control, automatically identifying anomalies and issuing alerts to ensure smooth operation. Integration with ERP and MES systems further enhances traceability and flexibility, reducing human intervention, improving safety, and minimizing failure rates.

Intelligent Warehouing

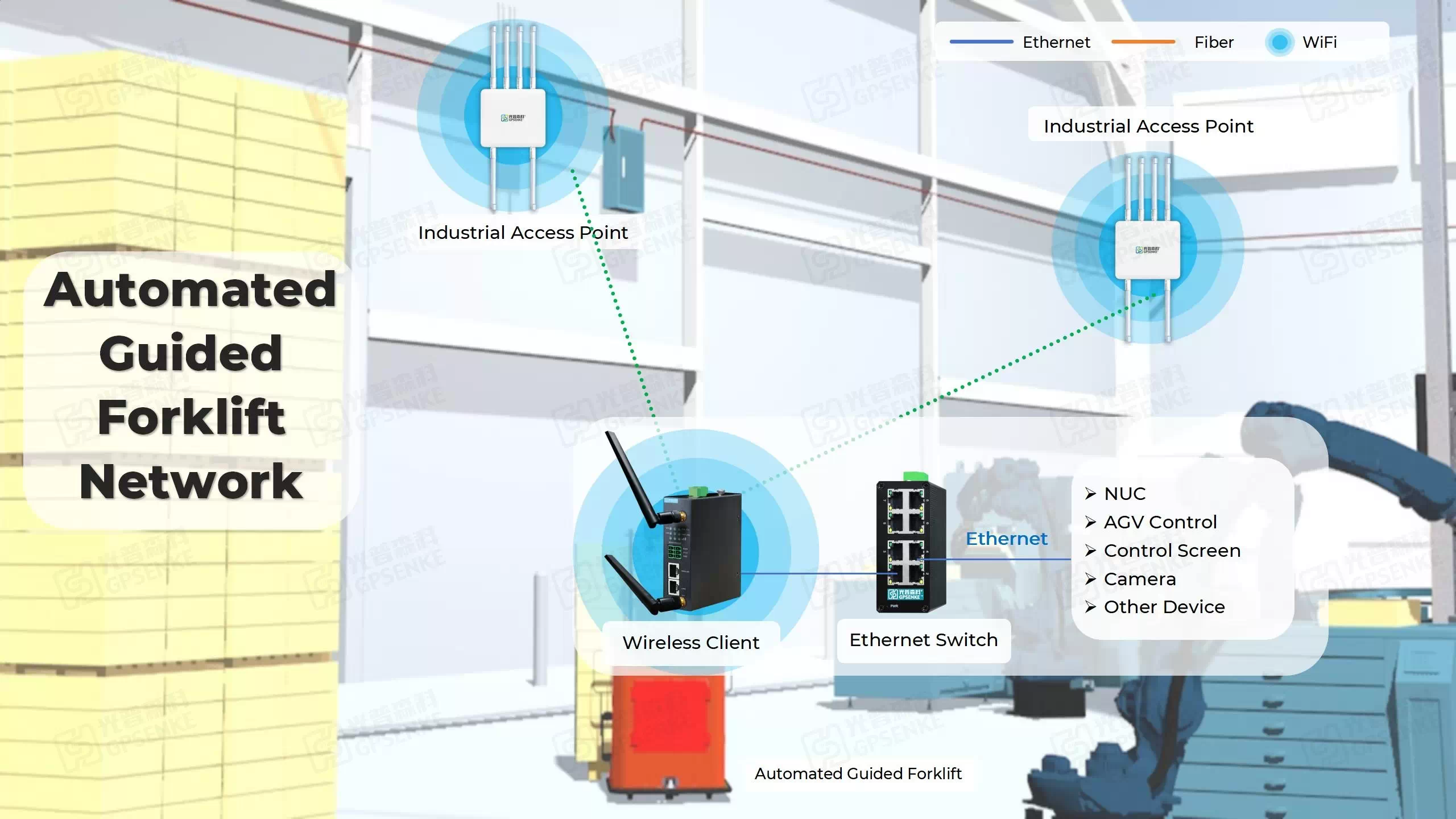

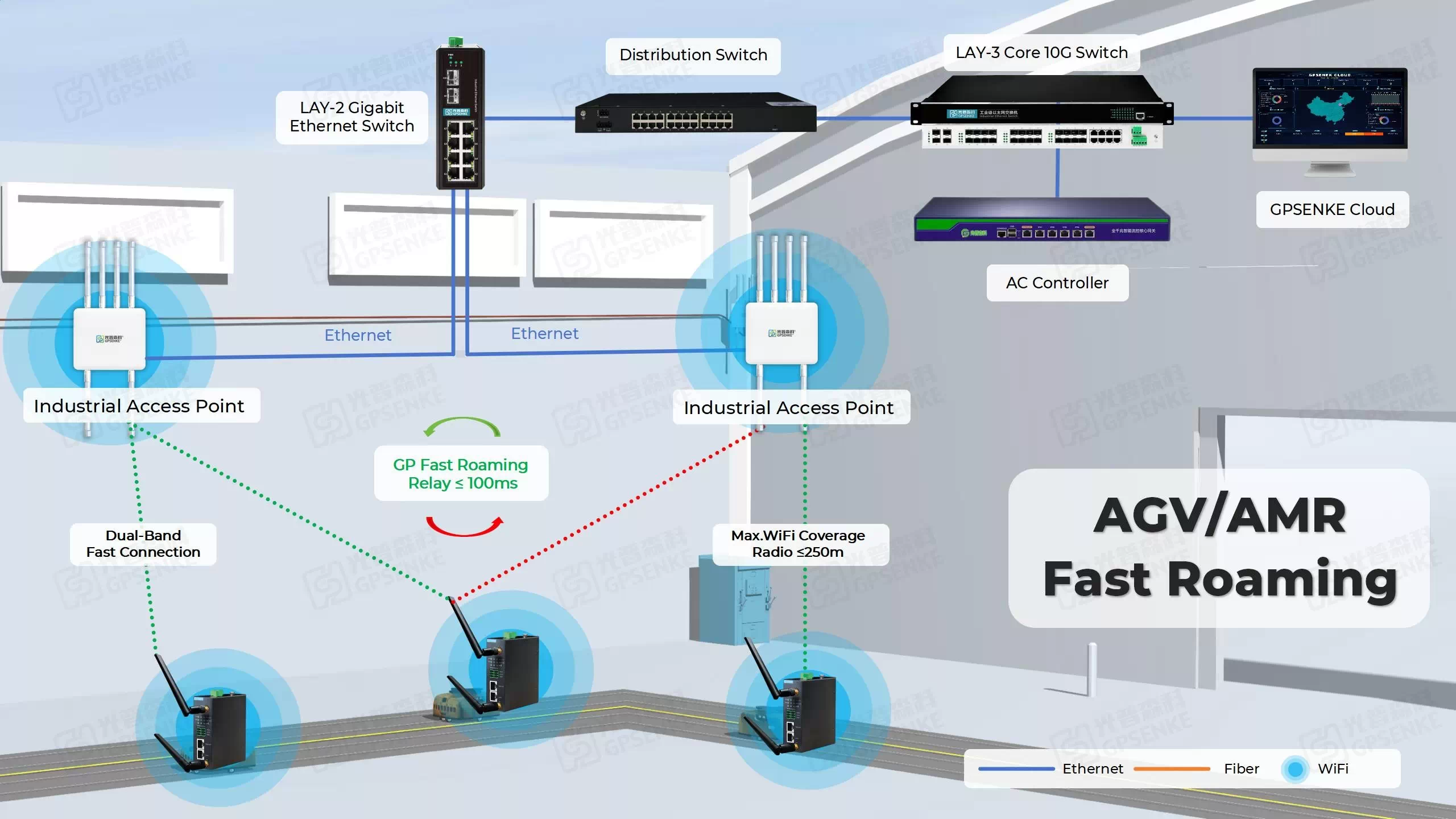

In intelligent logistics, seamless roaming and switching of automated transport devices such as AGVs, AMRs, and forklifts are crucial. Through wireless communication technology and intelligent scheduling systems, these devices can maintain real-time communication and smoothly switch between different areas in complex warehouse and production environments. The system can monitor device locations and status in real-time, automatically plan paths and scheduling, ensuring efficient operation, reducing transport delays, and improving overall warehouse management and material delivery efficiency.

Fast Roaming

High-Density

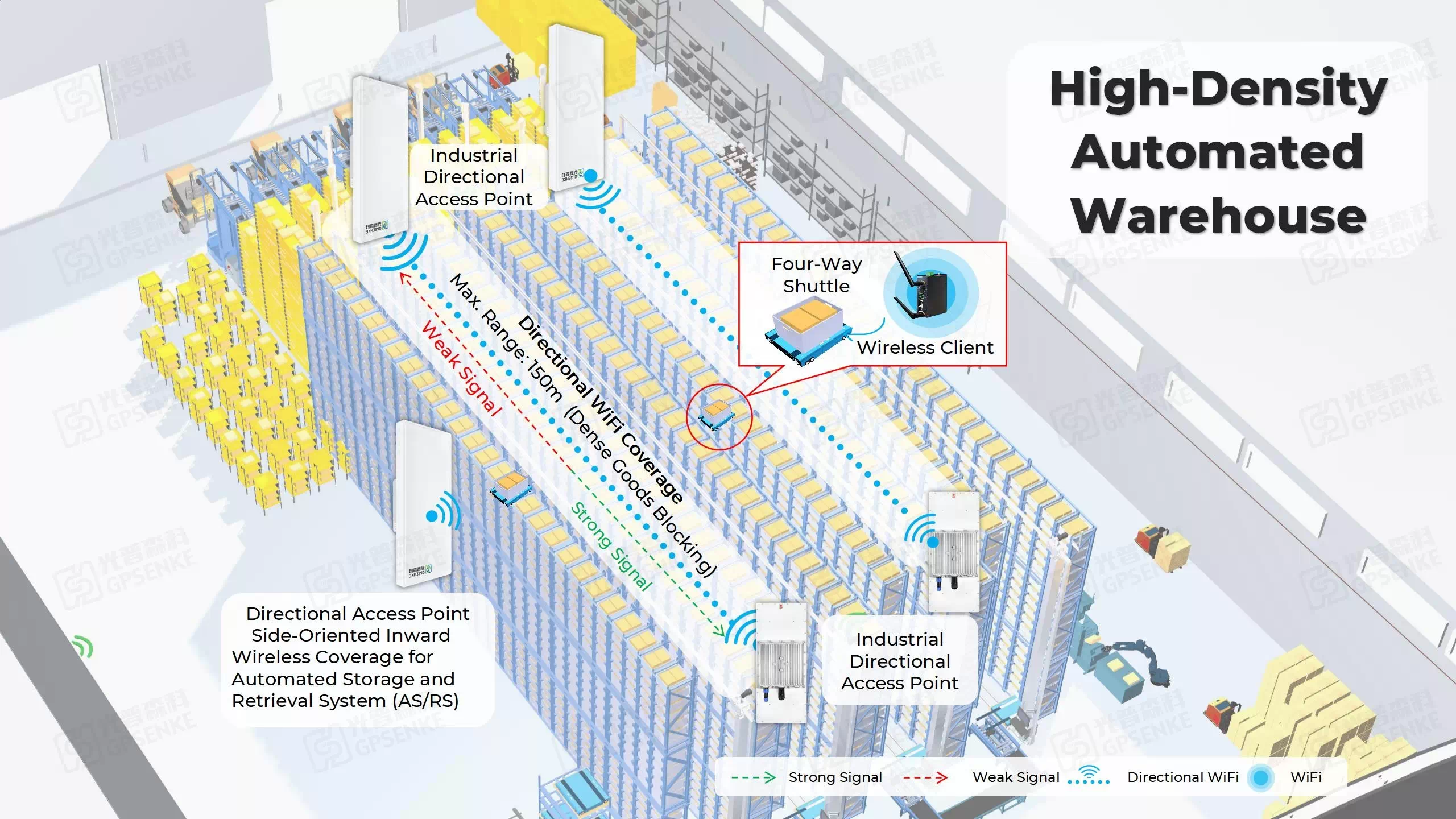

In high-density automated storage systems, intelligent warehouse management systems use IoT and real-time data analysis to precisely track the location, quantity, and status of every item. By deploying high-performance wireless APs on shelves, seamless wireless coverage is achieved across the entire warehouse, ensuring real-time data transmission and stable device connectivity. Four-way vehicles, an essential component of automated storage, rely on wireless networks to communicate in real-time with the system, transmitting location and item status. Combining IoT and real-time data analysis, the system can accurately locate every item, optimize path planning, and ensure efficient equipment operation.

Directional Wireless AP Selection

Directional wireless APs focus signals on designated areas, providing stable long-range coverage, reducing interference, and ensuring efficient connectivity for devices within high-density vertical storage, meeting high-speed data transmission requirements.

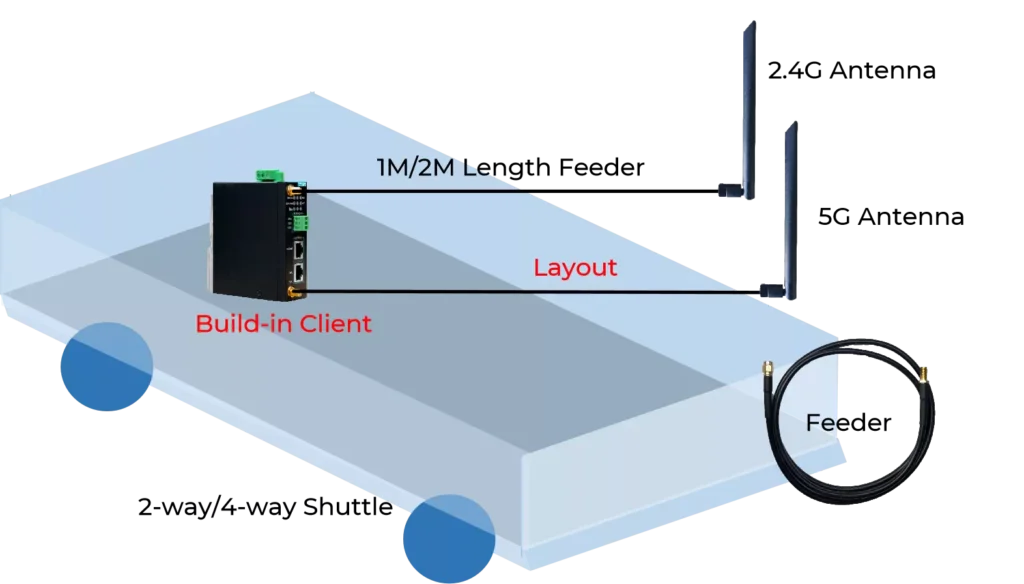

Two-way/Four-Way Shuttle Network

The built-in wireless client, combined with optimized antenna layout, ensures stable signal reception as AGVs move within high-density vertical storage, reducing network latency and improving operational efficiency.