Leading the Intelligent Transformation of the Steel Industry and Setting a New Standard for Unmanned Crane Scheduling!

-Project Background-

With the advancement of intelligent upgrades in the steel industry, a steel plant in Qian’an faces challenges related to high-risk, high-intensity, and low-efficiency overhead crane operations. To achieve unmanned scheduling and ensure safe and efficient operations, the steel plant has decided to implement a smart transformation project by introducing GPSENKE’s industrial wireless communication solutions, aiming to create an all-weather, stable, and high-precision unmanned overhead crane scheduling system.

-Solution Provided-

GPSENKE customized an industrial wireless communication solution tailored for this project. The key components include:

- Unmanned Crane Control and HD Video Transmission: Supports remote and precise scheduling, ensuring low-latency, high-reliability control commands.

- Industrial-Grade Wireless Network Deployment: Deployment of industrial directional wireless APs and point-to-point wireless bridges to cover key operational areas within the plant, enabling real-time transmission of HD video and control data.

- High Reliability and Environmental Adaptability: The devices are IP67 rated, with lightning and interference protection, ensuring stable and reliable operation in the high-temperature, dusty environments of the steel plant.

- Centralized Management and Remote Maintenance: The cloud platform allows real-time monitoring of device statuses, link quality, and alarm information, while supporting remote configuration and maintenance.

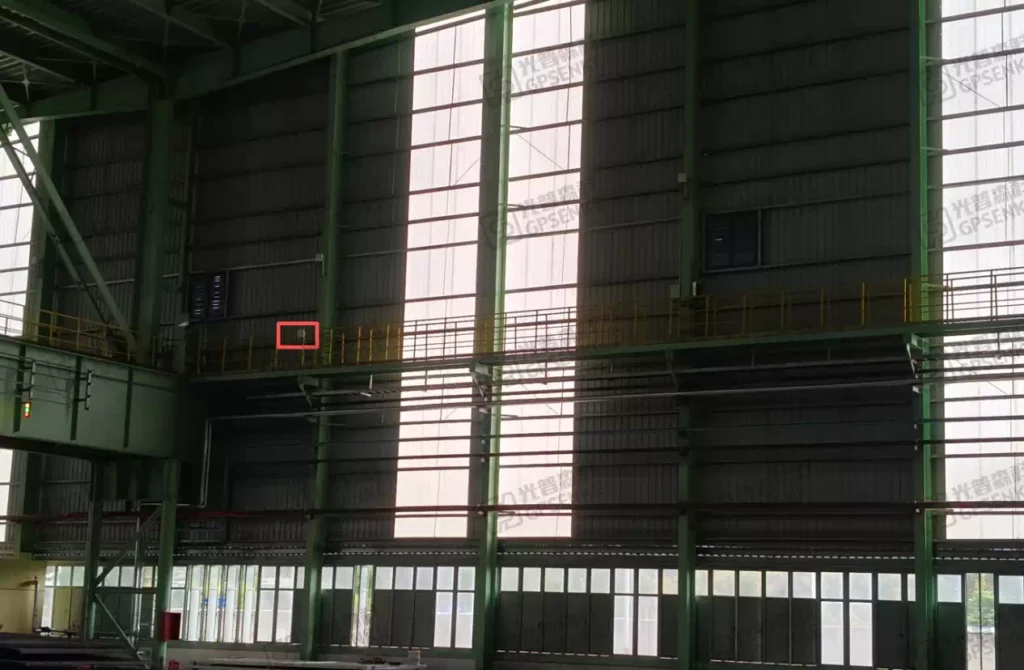

-Project Site-

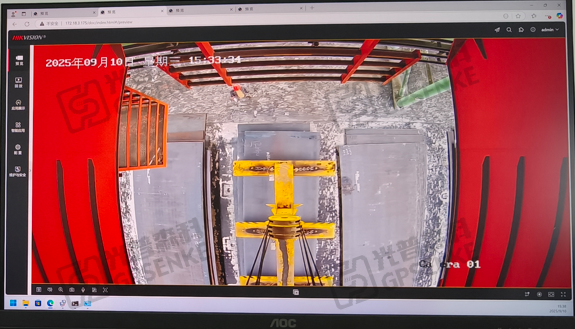

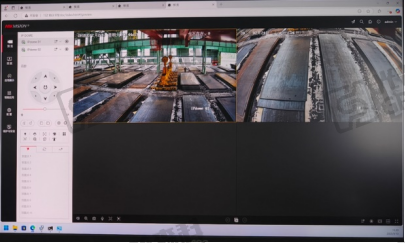

-Technical Test Onsite-

–Test Results–

After on-site testing and validation, the GPSENKE solution demonstrated excellent performance:

- Crane Control and Video Transmission Latency: Average latency of 2-6ms.

- Packet Loss Rate: Packet loss rate was either 0 or close to 0, meeting the required standard of <0.01%, demonstrating stable and reliable performance.

- Bandwidth Performance: Industrial wireless AP achieved 198 Mbps, while the industrial wireless bridge reached 145 Mbps.

- Video Clarity and Smoothness: HD video was transmitted without lag or delay, ensuring smooth and clear video transmission, meeting the demands of high-density operations.

- Overall Effect: Achieved all-weather unmanned scheduling, significantly enhancing production safety, operational efficiency, and management intelligence.

GPSENKE Directional Wireless AP Test Results

| Test Conditions | Small Packet (32 Bytes) | Large Packet (2048 Bytes) |

| Packet Loss Rate | 0% | 0% |

| Latency | Average latency≤6ms | Average latency≤6ms |

GPSENKE Industrial Wireless Bridge Test Results (Small Packet – 32 Bytes)

| Test Conditions | GPSENKE Industrial Wireless Client | Camera Data Transmitted by Client |

| Packet Loss Rate | 2 packet losses packet loss rate: 0.00% | 8 packet losses packet loss rate: 0.01% |

| Latency | Average latency≤2ms | Average latency≤3ms |

GPSENKE Industrial Wireless Bridge Test Results (Large Packet – 2048 Bytes)

| Test Conditions | GPSENKE Industrial Wireless Client | Camera Data Transmitted by Client |

| Packet Loss Rate | 0% | 0% |

| Latency | Average latency≤3ms | Average latency≤4ms |

GPSENKE Device Test Average Bandwidth

| Test Conditions | GPSENKE Wireless APs | GPSENKE Wireless Brigde |

| Bandwidth Rate | Average Rate:198 Mbps | Average Rate:145 Mbps |

-Conclusion-

The smart transformation project at the Qian’an steel plant highlights GPSENKE’s leadership in industrial wireless communication, HD video transmission, and unmanned control systems. With a stable, low-latency, and highly reliable communication network, the unmanned crane scheduling system operates safely and efficiently, providing a replicable success model for the steel industry’s intelligent transformation.

-About GPSENKE-

GPSENKE is dedicated to providing industrial-grade communication, automation, and data transmission solutions, serving industries such as steel, mining, energy, and logistics. The company focuses on the research and development of highly reliable, low-latency, and scalable network technologies, creating safe, efficient, and intelligent production and management environments for its clients.