Ensuring Efficient Data Transmission and Collection for Smart Operation Vehicles!

With the increasing automation and environmental demands in coke plants, vehicles like pusher cars and coal loading cars generate large amounts of operational data. This project uses Wi-Fi technology to efficiently collect and transmit this data to the central system, enabling better decision-making and timely fault warnings.

-Core Objective-

- Real-time wireless data upload from vehicles to enhance efficiency.

- Remote monitoring of vehicle status to improve safety.

- Ensure reliable wireless operation in harsh environments.

- Unified device integration for intelligent vehicle management.

-Technical Challenges-

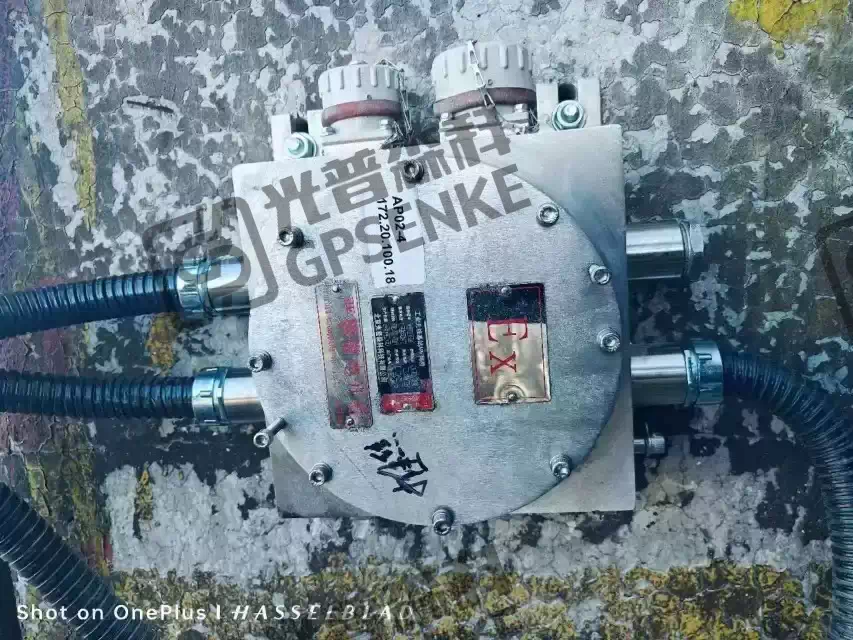

- Explosion-proof: Devices must meet safety standards in hazardous areas.

- Temperature Range: Equipment must work from -40°C to 75°C.

- Electromagnetic Interference: Devices must resist interference from inverters.

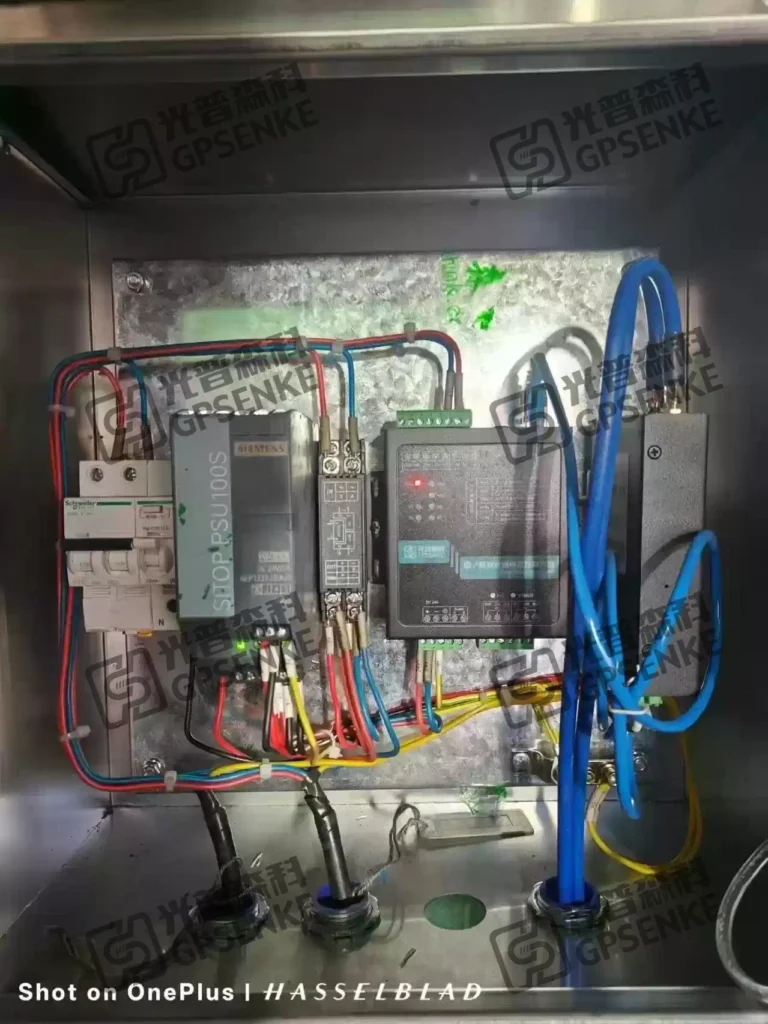

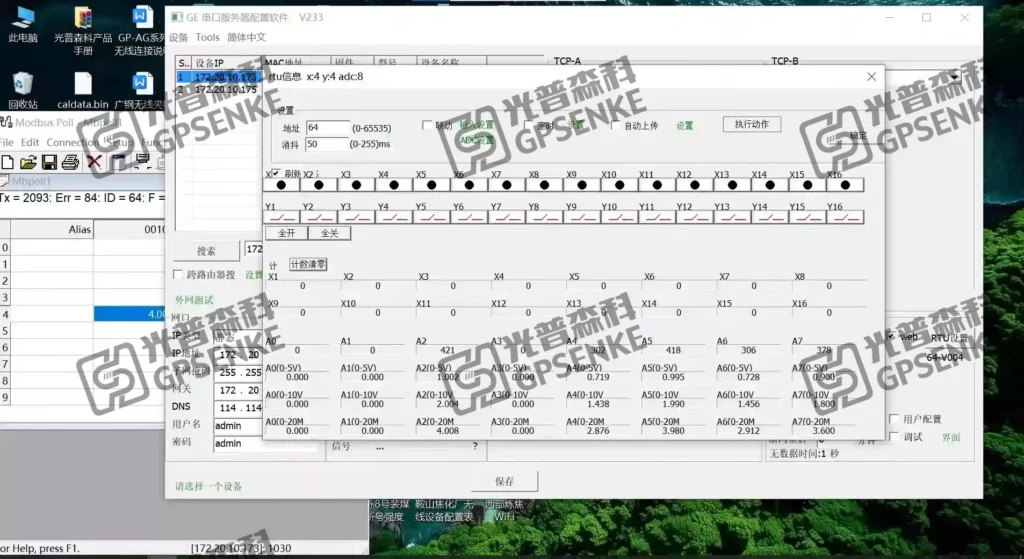

- Protocol Support: System needs to handle multiple industrial protocols.

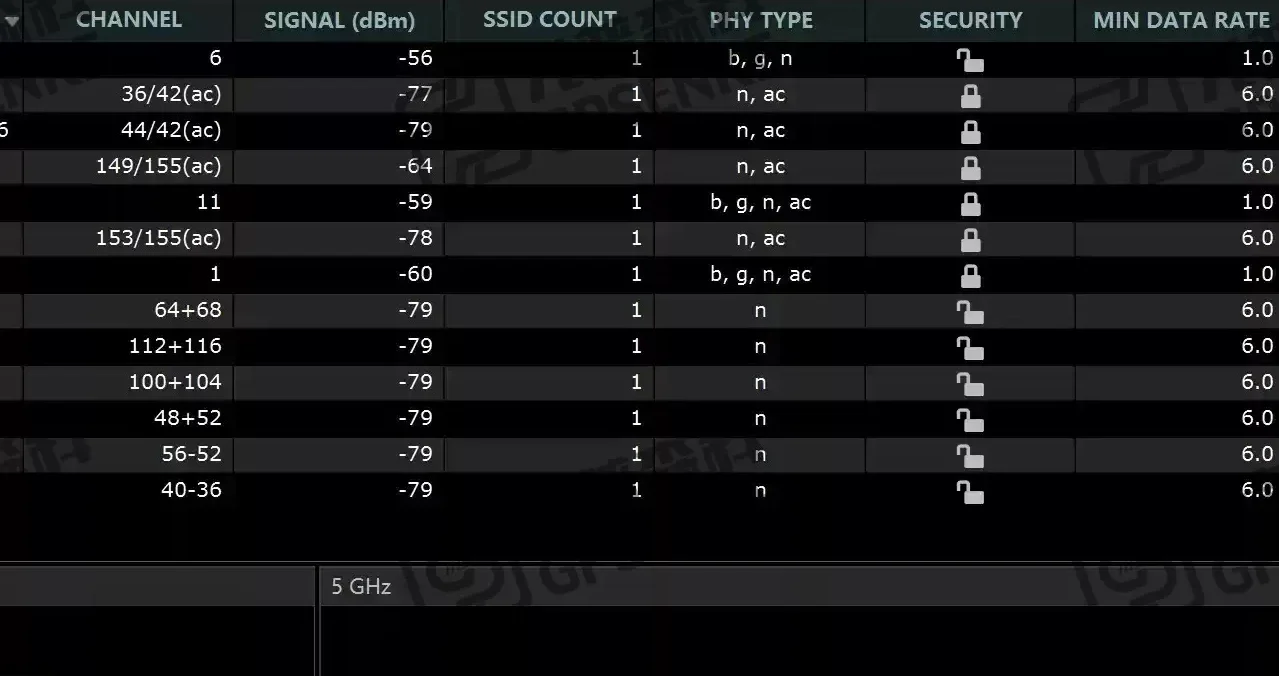

- Roaming: Fast, stable wireless switching during vehicle movement.

-Project On-site –

-Actual project results and customer feedback-

-Actual project results and customer feedback-

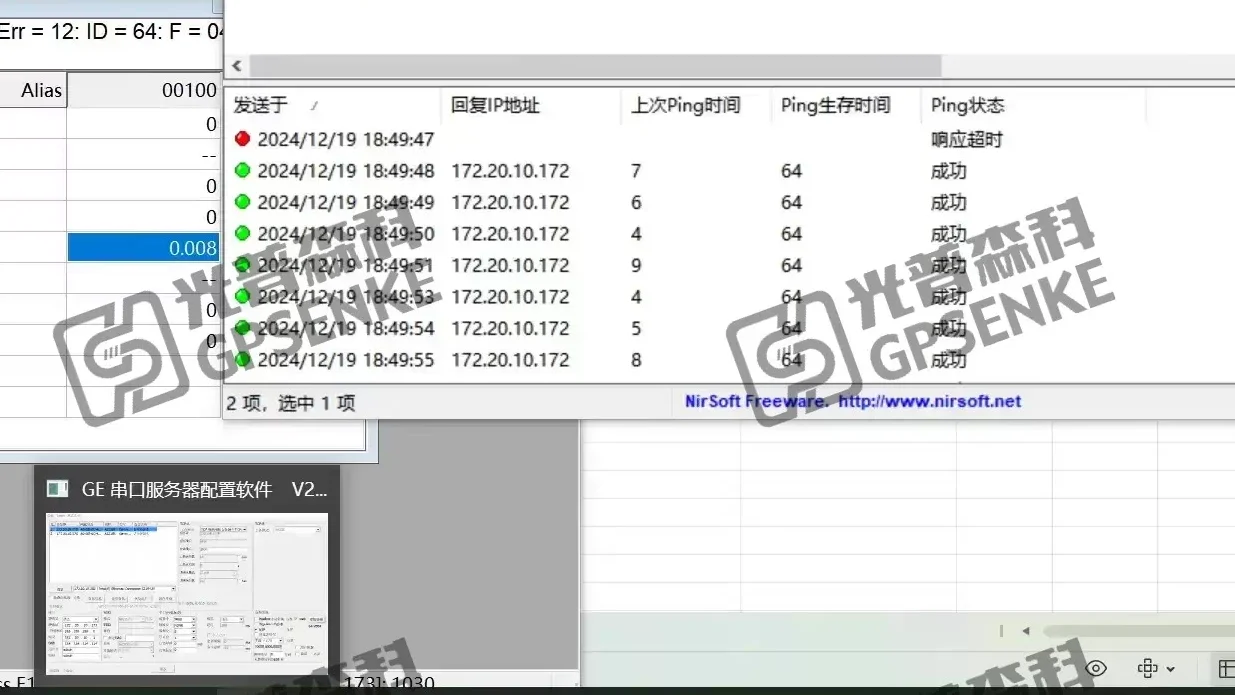

✅ Stable Data Upload: Data collection delay < 50ms, ensuring real-time visibility.

✅ Remote Monitoring: 80% reduction in on-site personnel, minimizing high-temperature risks.

✅ Reliable Network: Continuous operation for 90+ days in temperatures from -40°C to 75°C.

✅ High Protocol Compatibility: 100% device integration with PLC, IO, Modbus, etc.

Client Feedback: Since system launch, it has run stably without any failures. The client highly recognizes the communication quality and project implementation capabilities!